Atomic Layer Deposition

Introduction:

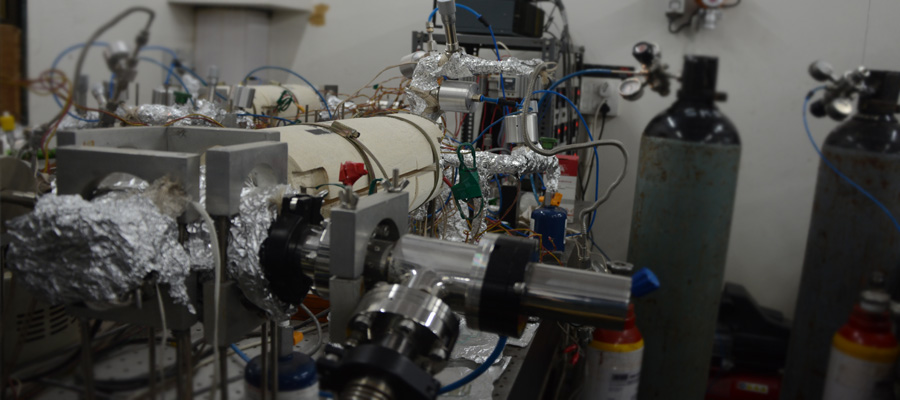

Atomic Layer Deposition (ALD) is a gas phase thin film deposition technique involving sequential and self-limiting surface reactions. ALD provides uniform, pin hole free, conformal films on a variety of substrates.

Make and Model:

Custom built Atomic Layer Depostion (ALD) reactor equipped with 10 Torr capacitance manometer, Baratron. Constant flow of 99.999% N2 gas controlled by Mass flow controller (MFC) maintains the required pressure inside the reactor maintained by constant pumping by a rotary pump.

Specification/Features:

- Uniform temperature of the reactor walls is maintained by ceramic heaters controlled by Eurotherm.

- In-situ Quartz Crystal Microbalance (QCM) measurements are possible to measure the growth rate of films deposited.

- In-situ four probe measurement technique exists for electrical conductivity measurements during film deposition.

- In-situ fourier transform infrared (FTIR) set up present for studying the surface chemistry of ALD films.

- Separate reactors available for deposition of oxide, nitride, sulphide and organic films to avoid contamination.

Whether facility is open to external users? : No

Location:

Devices and Interfaces Lab, Transit building, 2nd Floor, IIT Bombay, Powai, Mumbai-400076.

Contact Details:

Convener/Incharge Name : Prof. Shaibal K. Sarkar,

Dept, of Energy Science and Engineering.

Email – shaibal.sarkar@iitb.ac.in